A CNC machine shop deals in manufacturing using state of the art equipment. It can be as small as a single room or as big as a whole company. Machining is a process wherein a material is reduced by physical processes to reveal the finished product with the desired shape, size, and texture. The controlled removal is also known as subtractive manufacturing. Shops of this kind are important in the car industry, the aircraft industry, the machine industry, and so on. Some brands have their own while others make the design and outsource the process to specialists.

Types of Materials Used

Machinists often deal with different types of metal. You can often see brass, copper alloys, aluminum, steel, alloy steel, stainless steel, and titanium in these shops. However, they can also use the same techniques on plastic, wood, ceramic, and composite materials. The choice will depend on the requirements of the product. You will have to determine if it needs to have a high degree of resistance to corrosion, heat, or pressure. You will have to consider whether the material must be malleable, stable, strong, conductive, economical, formable, weldable, lightweight, sturdy, bio-compatible, or easy to handle. There are plenty of options for different applications.

Types of Machine Tools and Operations

There are three main machining processes: turning, drilling, and milling. Turning involves the rotation of the workpiece while a cutting tool removes material from the surface. A good example would be lathes. As for milling, it is the cutting tool that rotates so that its edges can have the force necessary to remove pieces of the material. Drilling is when there is a need to create holes or to refine them. Drill presses are often used for this process. There are also miscellaneous operations that may be performed by machining tools such as burnishing.

The Business of a Machine Shop

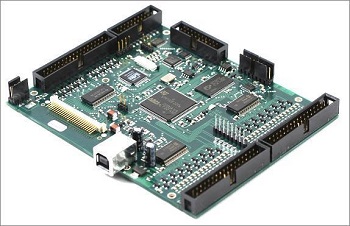

It can be difficult to start a business that deals with machining, primarily because of the high cost of the equipment. Interested parties must raise a large capital in order to acquire the necessary machines in production. The processes are also labor-intensive and require considerable technical expertise. Machinists have to be well-trained individuals that can comprehend complex plans, operate modern machines, and implement safety measures. Newer machines that have computer numerical control or CNC machine shop are much easier to use for large-scale operations as they can be automated. However, they will still need intervention from time to time.

When repairs no longer suffice, it’s time for an upgrade. Get a

When repairs no longer suffice, it’s time for an upgrade. Get a